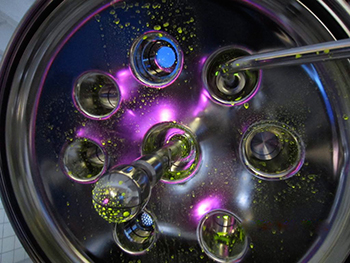

Process Vessel – the basis for perfect processing

All kinds of processes must be able to run smoothly in a process vessel.

With products from Bolz & EDEL, you can rely on the vast experience of our experts in layout, design and production and thus create the best conditions for the perfect process flow in your company. Companies in the chemical and pharmaceutical industries are equally well served by our process tanks and vessels as are companies from the food industry and breweries.

Across all industries, the correct processing and storage of raw materials and products is an important step on the way to an excellent end product.

As a vessel manufacturer, we are happy to accompany you on this path, equipped with extensive knowledge of the industry, the most modern production methods and with competent advice.

Crucial for us: Not all vessels are the same – and not all customers are the same! Responding to an enquiry from you, we work out the optimal version of the process vessels based on your personal wishes and requirements, and which are perfectly tailored to the needs of your company.

Bolz & EDEL process vessels have stood for quality and reliability in the area of process vessel construction for many decades.

Your Options

… in the areas of process vessels and process vessels

- Pressure vessel / pressure tank

- Process vessel / process tank

- Storage vessel / storage tank

- Batch/preparation tank / batch/preparation tank

- WFI vessel / WFI tank

- PW vessel / PW tank

- Stirring tank / Stirring tank

- Vacuum vessel / Vacuum Tank

- Fermenter / bio fermenter

- Reactor / bioreactor

- Inactivation vessel

- Mobile vessels

- … and much more

Your Variants

… for the individual process vessel and process vessel:

- From 10 L batch/ preparation tanks to 240,000 L WFI pressure tanks

- Surfaces of up to Ra 0.3 µm polished and electropolished

- Materials 1.4301, 1.4404, 1.4435, 1.4571, 1.4539, …

- Heating systems / cooling systems

- Hot and/or cold insulation

- All necessary connections

- A wide selection of fixtures and fittings

- Manholes, openings for inspections

- Stirrer, magnetic stirrer

- Fittings, valves, safety devices

- 3-D monitoring of cleaning

- Documented Maintenance/ Quality Checks / FAT

- Documentation suitable for pharmaceuticals

- … and much more

What can we do for YOU?

Do you have any questions, or do you require a quote? Please contact us at any time and our experts are happy to help you out.