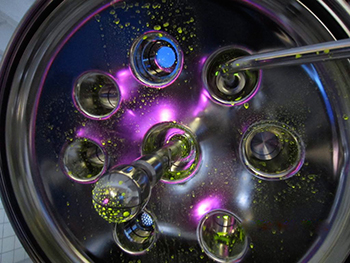

Stirring tank – sophisticated technology for the best results

Not all tanks are created equal! Special stirring tanks are required when liquids, mixtures, suspensions etc. have to be kept in continuous circulation. This is often the case in chemical and pharmaceutical companies, but such systems are also often used in the food industry. Stirring tanks from the Bolz-EDEL Group can be used in a large number of different industries and facilitate handling when processing a wide variety of products.

We implement a wide variety of requirements and quality specifications from our national and international customers effectively with excellent industry knowledge and technical know-how. In order to achieve this, we work for you with designs in 3-D, the most modern production technologies and with highly trained skilled workers. It is very important to us that our stainless-steel stirring tanks not only make a positive contribution to the efficiency of your business process, but also that they simplify your and your employees’ work easier.

We treat every customer specially! We know that every company has very individual wishes and expectations when it comes to equipment, machines and processes. We therefore offer a multitude of possible variations of stirring tanks, and following your requirements, we create the perfect version for you.

However, one thing always remains constant: the high level of quality and reliability for which Bolz & EDEL have stood for many decades!

Your Options

… in the areas of stirring tanks:

- Pressure vessel / pressure tank

- Process vessel / process tank

- Storage vessel / storage tank

- Batch/preparation tank / batch/preparation tank

- WFI vessel / WFI tank

- PW vessel / PW tank

- Stirring tank / Stirring tank

- Vacuum vessel / Vacuum Tank

- Fermenter / bio fermenter

- Reactor / bioreactor

- Inactivation vessel

- Mobile vessels

- … and much more

Your Variants

… for the individual stirring tank:

- From 10 L batch/ preparation tanks to 240,000 L WFI pressure tanks

- Surfaces of up to Ra 0.3 µm polished and electropolished

- Materials 1.4301, 1.4404, 1.4435, 1.4571, 1.4539, …

- Heating systems / cooling systems

- Hot and/or cold insulation

- All necessary connections

- A wide selection of fixtures and fittings

- Manholes, openings for inspections

- Stirrer, magnetic stirrer

- Fittings, valves, safety devices

- 3-D monitoring of cleaning

- Documented Maintenance/ Quality Checks / FAT

- Documentation suitable for pharmaceuticals

- … and much more

What can we do for YOU?

Do you have any questions, or do you require a quote? Please contact us at any time and our experts are happy to help you out.